MB'AIR

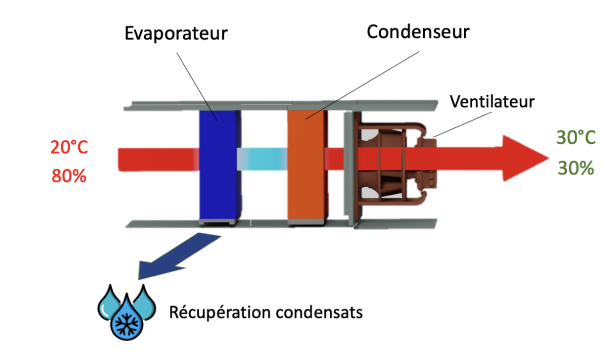

MB’air is a thermodynamic dehumidification system. It facilitates pesticide-free cultivation and provides energy savings by eliminating the overconsumption of energy associated with dehumidification through heating and ventilation.

It can blow the treated air in open field or through an air duct for uniform distribution. There are many possible installation options, such as along the gables, outside, or at height.

Available capacities: 8 – 12 – 24 – 36 liters/hour at 20°C and 80% humidity.

Monoblock Thermodynamic Dehumidifier for Greenhouses

Possible applications:

- Crops maintained above 10°C

- New or existing greenhouses

- Outdoor installation

- Integrable in semi-closed greenhouse corridors

- Usable for crops placed on gutters or directly on the ground.

The system features ventilation with the ability to adjust airflow rates according to needs. In circulation mode only, high airflow rates can be achieved.

The refrigerant used is R32, which has a low global warming potential. These next-generation fluids, unlike the most commonly used fluids today (such as R410A, R134a, R407C), will remain easy to supply and competitively priced in the coming years.

For regulation, MB’air is available in two versions:

- A climate computer-controlled version

- An autonomous version with a humidity sensor.

MB’air can be used to blow air in open field or through ventilation ducts to distribute the treated air in different areas of the greenhouse. These options allow for uniform distribution of the treated air throughout the greenhouse, thus promoting uniform plant growth.

Features

- Construction in galvanized steel and aluminum with anticorrosion polyester paint.

- Scroll hermetic compressor for robustness and high performance.

- Coils with copper tubes and aluminum fins.

- Power supply: 400V/3+N+T/50Hz.

- Next-generation thermodynamic fluid R32 GWP 675 or R454C GWP 149.

- Remote monitoring available via Ethernet or 3G/4G.

Advantages

- Can blow air through a duct for uniform air distribution.

- Can be integrated into the climate corridors of semi-closed greenhouses.

- Multiple installation options: under gutters, at height, and outdoors.

- High-performance EC fan with variable speed technology.

- Climate computer-controlled version and autonomous version with humidity sensor.

- Available in axial fan version for open field blowing and radial fan version for ducted air distribution.

- Eligible for AGRI TH-117 Energy Savings Certificates.

Free-Cooling:

regulation of the outdoor air intake.

Wheels for easy movement from one place to another within the greenhouse.

Autonomous regulation based on relative humidity or water deficit.

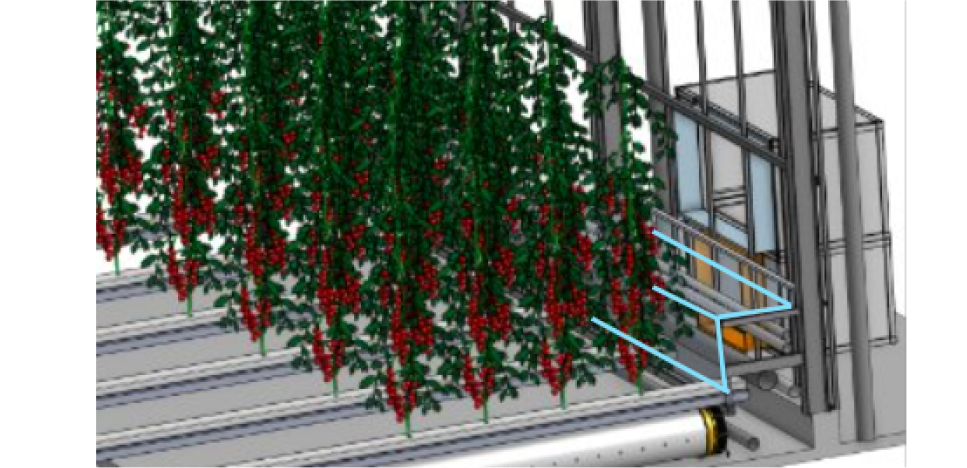

Installation of air ducts for air distribution.

Circulation mode with variable speed.

- Energy efficiency: Keeps the greenhouse closed to retain heat, thereby reducing energy consumption by at least 15%.

- Optimization of plant growth: Removes excess moisture that slows plant growth and promotes mold and diseases.

- Improvement of light and climate: Reduces the formation of droplets on leaves and fruits, thereby increasing brightness and promoting an optimal climate without pesticides.

- Additional heat: Releases heat during operation, reducing the demand on the greenhouse heating system.

- Installation flexibility: Easily integrates into new or existing greenhouses, whether standard or semi-closed.

- Versatility of crops: Suitable for various sheltered crops with temperatures above 10°C, including tall crops such as tomatoes, cucumbers, and peppers.

- Uniform distribution: Uses air ducts for smooth and uniform distribution of treated air.

- Control and automation: Available in climate computer-controlled version or autonomous version with humidity sensor.

Possibility of optimized installation outside the greenhouse.

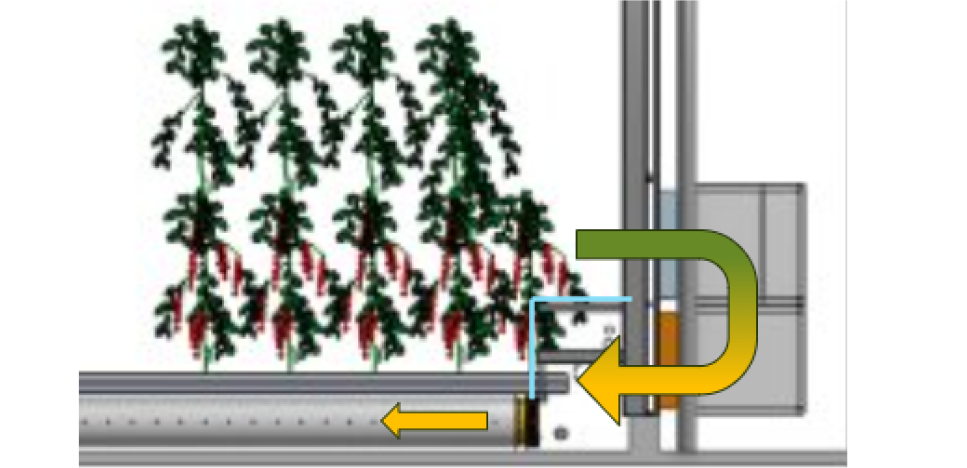

The machine, placed outside the greenhouse, draws in air via the green arrow at approximately 1.50 meters in height, preventing any bypass of dehumidified air, and then blows it into the mixing zone at the base, shown in blue and made of polycarbonate and/or a transparent plastic cover. This mixing zone receives the dehumidified air, preventing any backflow, and the duct fans located under the gutters draw in a mixture of greenhouse air and dehumidified air. The combined airflow of the duct fans (2.5 vol/h) exceeds that of the dehumidifier (1 vol/h), ensuring uniformity throughout the greenhouse. This option is customizable based on the desired machine dimensions and the specific needs of the greenhouse. For more information, please contact us directly