EXT'AIR

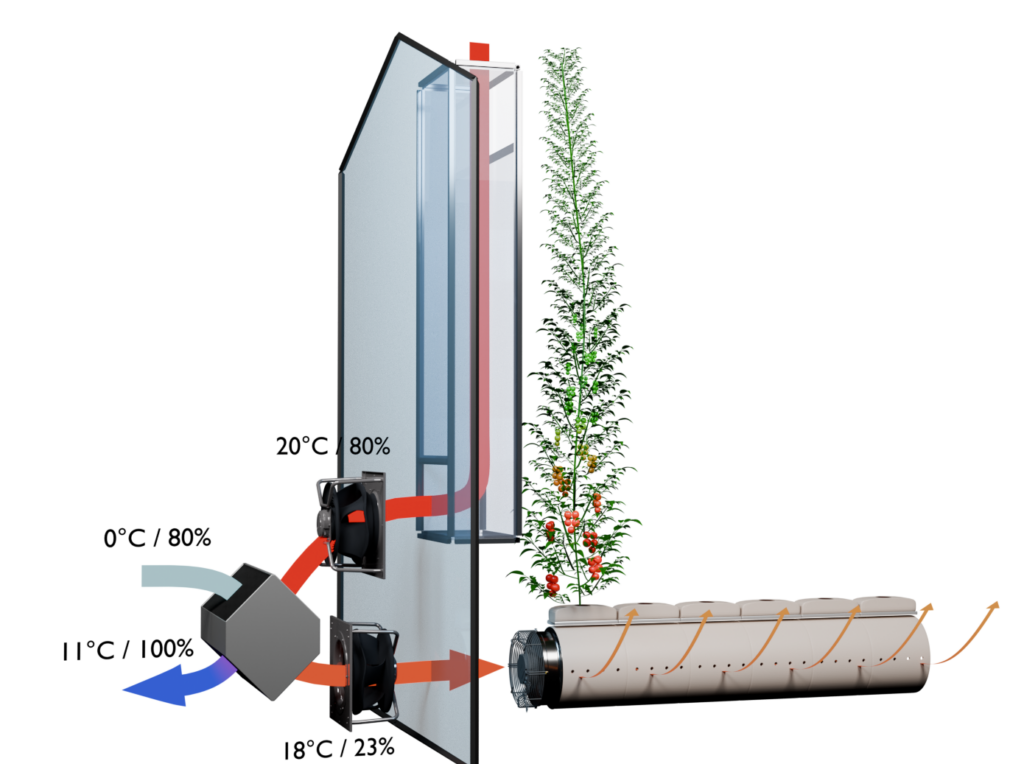

The controlled ventilation dehumidifier with the EXT’Air double-flow heat exchanger stands out for its energy efficiency, dehumidification power, and the uniformity of the air distributed within the greenhouse. It ensures a constant renewal of the indoor air while recovering heat from the extracted air to preheat the incoming air.

With Ext’Air, reduce heat waste related to dehumidification and achieve significant energy savings. By keeping the greenhouse closed for longer periods, you limit heat losses, which helps reduce the use of high and low-temperature heating systems.

Moreover, the outside air used for dehumidification recovers heat before entering, further optimizing savings.

By choosing Ext’Air, you benefit from double energy savings: less heat lost through openings and preheated incoming air.

Thermodynamic dehumidifier with outdoor air and double-flow heat exchanger

Possible applications:

- Any crop under shelter > 15°C

- Compatible with new or existing greenhouses

- Ideally installed for crops on gutters

- Ideally suited for sites with limited electrical powe

The EXT’air system is equipped with a high-efficiency double-flow heat exchanger, allowing it to recover nearly 90% of the heat from the extracted air. It features two variable-speed fans that automatically adjust ventilation based on actual needs, thereby optimizing energy performance. The ventilation speed is controlled by the climate computer. If no climate computer is available, or if it lacks the program for managing the double-flow system, the controller, programmed by AirGaïa and configured by the grower, will provide precise control of the fans. The control interface allows for easy and intuitive management of the system, with advanced programming options.

Why choose EXT'air?

EXT’air and MB’air are two high-performance solutions tailored to different energy needs in greenhouses.

EXT’air uses only the energy from two fans. It helps maintain a high level of temperature and humidity uniformity, providing an optimal environment for crops with low energy consumption. EXT’air is also the solution for sites with limited available electrical power.

MB’air, on the other hand, generates heat when operating, which further reduces boiler consumption. It can be the best option for greenhouse operators with high heating bills, enabling them to make substantial savings on heating costs.

The choice between EXT’air and MB’air therefore depends on your energy situation. If you have sufficient electrical capacity available in your greenhouse, the MB’air solution offers even greater energy savings. However, if your electricity rates are high, EXT’air proves to be an economical and efficient solution.

Features

- The outdoor air intake and the extracted air outlet are positioned in such a way that air short-circuits are avoided.

- Rain guards and anti-wildlife grids on the outdoor air intake.

- Design allowing the passage of the cleaning robot; the lower rail may need to be adapted.

- The fresh air flow is 1 to 2 Vol/h, complemented by the duct fans with a flow rate of 2 to 2.5 Vol/h.

- Remote monitoring available via Ethernet or 3G/4G.

Advantages

- Designed to integrate into existing greenhouses, taking into account wall penetration constraints, the presence of collectors along the gable, and the passage of the cleaning robot.

- The double-flow heat exchanger and fans are made of polymer resistant to corrosion caused by sulfur vapors from preventive treatments against powdery mildew.

- High airflow rate up to 9000 m³/h with variable speed fans.

- Climate computer-controlled version and autonomous version with humidity sensor and water deficit regulation.

- Energy efficiency > 85% and very low electrical consumption.

- The design of the mixing zone and its air connections ensure very uniform air distribution within the greenhouse.

Outdoor air intake:

The outdoor fan can operate alone to cool the greenhouse or create overpressure.

Outdoor air filtration: Washable galvanized steel filter, or customizable upon customer request.

Climate computer-controlled version and autonomous version with humidity sensor and water deficit regulation.

- Heat recovery: The system allows for optimal heat recovery, thus improving energy efficiency.

- High dehumidification capacity

- Low energy consumption: The device is designed to consume minimal energy for maximum savings.

- Fully controllable from the climate computer

- Air uniformity in the greenhouse: The combination of EXT'air with the mixing zone and duct fans provides high airflow rates and eliminates any microclimates.

Optimized installation outside the greenhouse

The warm air from the greenhouse is collected at the top and then descends into a chimney where it is drawn in by a fan. This fan mixes a small amount of air from the greenhouse with pre-heated outside air using recovered heat. A stretched plastic cover creates a buffer mixing zone about 60-80cm deep.

The mixed air is then blown through ducts with fans, ensuring a high airflow rate and a uniform climate. This flexible system allows a single unit to serve one, two, or three sections, thus meeting the various needs of the greenhouse while ensuring maximum efficiency.

This option is customizable based on the desired machine dimensions and the specific needs of the greenhouse. For more information, please contact us directly.